Compressed Air Filtration for The Food and Beverage Industry

Walker Filtration understands the importance of exceptional air hygiene in the food and beverage industry. Our innovative solutions are designed to offer safe air quality for food production.

Posted on September 19th, 2022

Compressed air and gas filtration is a critical part of the food and beverage industry. It is used in processes such as sorting, cutting, canning, blowing-off surfaces and shaping consumables.

The air and gas used in these processes must be free of contaminants before contact or non-contact with food products. Sources of contamination can include particles, microorganisms, water, and oil. Good filtration is essential and makes products cleaner and safer, prolonging their shelf life and improving their taste.

This article discusses the many uses of compressed air and gas in the food and beverage industry, as well as the recommended compressed air purity designations depending on the process for which compressed air is used.

The Many Uses of Compressed Air

There are tens of thousands of factories in the food industry that all use compressed air. Some of the most common uses include:

- Cleaning Machines: Foods that leave behind crumbs, such as baked goods, need to be thoroughly cleaned. Compressed air is used to clean the machines periodically.

- Guiding Products: Pneumatic pushes use compressed air to operate and help maintain the flow of food products and equipment.

- Product Cleaning: Mostly in fruit and vegetable plants, compressed air is used for cleaning the produce and the containers they are placed in.

- Drying Produce: Many facilities use compressed air to dry off fruits and vegetables after they have been washed.

In the beverage industry some of the more common uses include:

- Fermentation Processes: Compressed air is used to increase oxygen levels to speed up the fermentation process.

- Water Sterilization: Using compressed air to create ozone gas that is used to sterilize water.

- Sealing Bottles: Pneumatically powered machines that use compressed air to operate are used to seal bottle caps.

- Bottling Beer: This is one of the most known uses of compressed air within the beverage industry. Compressed air is used in the process of bottling beer to reduce the residual oxygen content. Air compressors are also used to flush beer bottles with CO2 using pneumatically powered machinery.

Legal Requirements of Compressed Air in Food and Beverage

A high level of hygiene is necessary in the food and beverage industry. Each food and beverage processing plant will have unique requirements of food safety and quality set out by local regulatory entities. There are strict international standards, such as ISO 8573-1, Safe Quality Food Institute, and the FDA, to ensure a high quality product is produced.

Depending upon the nature of the application and the type of impurities to be removed, different filtration methods will be required. It is important to understand these requirements so that appropriate cost-effective filtration is applied.

Types of Compressed Air Used in Food and Beverage Production

There are generally three different types of compressed air systems in the food and beverage industry. Each require different levels of compressed air purity:

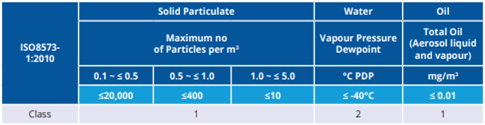

Contact: This compressed air comes in direct contact with food products. The compressed air must undergo stringent air treatment to guarantee air purity and ensure food safety. The compressed air purity designation for contact air in food / beverage production is ISO 8573-1 2010 [1:2:1] (see Fig. 1 below).

For contact air, maintaining the correct dewpoint is essential to prevent microbial growth. There are multiple solutions to achieve this dewpoint and high standard compressed air suitable for contact air. This includes air treatment with absorption-type compressed air dryers in the compressor room, and at point of use if needed in your facility.

High efficiency coalescing filters are also required to remove particulate, oil aerosols and vapor prior to the desiccant dryers. High efficiency particulate filters at the downstream of the desiccant dryers help remove any desiccant dust. To achieve ISO8573-1:2010 Class 1 for particulate a high efficiency filter providing particle reduction down to 0.01 µm (at an efficiency of 99.9999%) is required.

Additionally, an activated carbon filter can remove remaining oil vapor that may cause contamination within your contact air, preventing product spoilage.

Fig.1 Minimum Recommended Compressed Air Purity Designation for Direct Contact with Food.

Non-Contact High-Risk: This is compressed air that is used in the production environment. While it does not directly encounter the food product, it is exhausted into the local atmosphere where the food is being prepared, processed or packaged. For example, if compressed air is used to create packing that will later include food product, this is a non-contact high-risk system. If un-treated, moisture, oil, particulate, and microorganisms in the compressed air may contaminate the surrounding environment and packaging that comes into contact with the food. Because of this, this type of compressed air should be held to the same purity standards as contact compressed air.

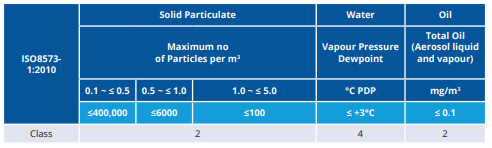

Non-Contact Low-Risk: This compressed air is mostly used in pneumatic systems and ‘plant air’ applications to that do not encounter food products. It is also used on surfaces that will come into contact with the food. For example, non-contact low risk compressed air will be used to power machines, control valves and air motors. This compressed air does not need the same purity standard as contact air or non-contact high risk. It is recommended that the minimum compressed air purity designation for non-contact low risk air used in food and beverage production is ISO 8573-1 2010 [2:4:2], and a pressure dewpoint of 37°F (3°C) is maintained.

Fig.2 Minimum Recommended Compressed Air Purity Designation for Non-food Contact

Walker Filtration’s Offerings

Walker Filtration provides safe and reliable filtration for the food and beverage industry. Our Alpha series provides the highest quality compressed air and are ideal when in-place steam sterilization is not required. The range includes Water Separators, Coalescing Filters, Particulate Filters, and Sterile Filters. With various grades available, you can have the confidence that the compressed air used in your food processing plant is free from moisture, oil vapor, dust particulate, and microorganisms that could contaminate your product.

Desiccant (adsorption) dryers such as Walker Filtration’s PROSFD Models, are also available to guarantee consistent dewpoint of -40°F (-40°C), and lower if needed. Microorganisms need a humid environment to grow, and you can preserve and protect your end product from contamination and spoilage by using a desiccant dryer to control the moisture levels in your food and beverage compressed air system.

Walker Filtration has over 35 years of experience engineering innovative products to meet various compressed air needs – Contact our sales team today: sales@walkefiltration.com or call us at +1 (814) 836-2900.

Read more about food and beverage grade compressed air 0n the website for the Safe Quality Food Institute (SQFI).